About Us

Cable Technology Laboratories, first founded in 1978, is an independent laboratory specializing in the study and testing of power and control cables, accessories, and other related electrical equipment of cable systems.

The facilities include modern test equipment for the evaluation of extruded, laminar and overhead cables. Electrical, physical, and mechanical testing is patterned to meet customer needs. The work is supervised by specialists having more than 30 years of experience in the manufacturing and testing of extruded and laminar cables and accessories. Laboratory technicians provide responsive direct support to staff members, assisting them to expedite problem-solving.

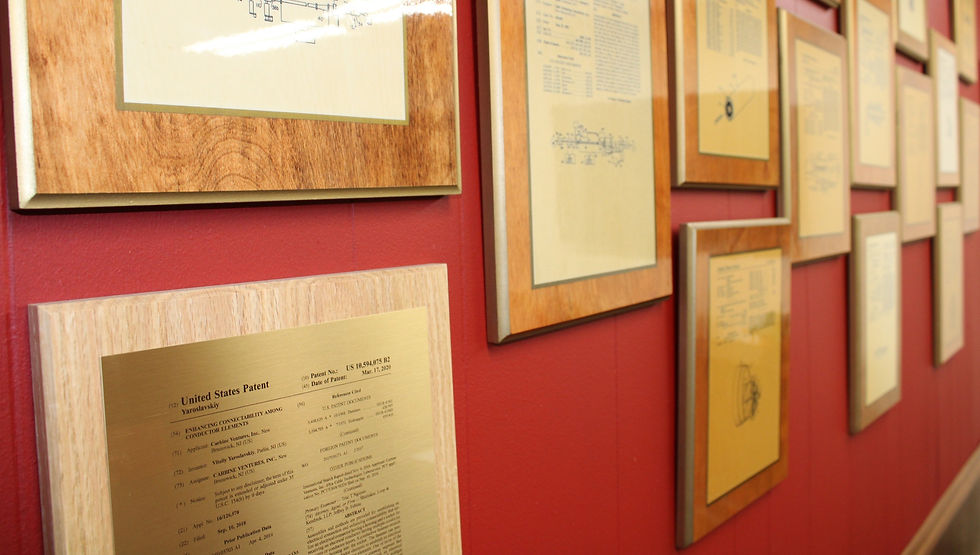

Our specialists have conducted R&D programs which have resulted in numerous technical papers and USA/Foreign patents pertaining to the design, manufacture, and testing of power cables and components. A list of pertinent technical articles is available upon request.

Our Policy To Quality

Cable Technology Laboratories (CTL) is committed to the continual improvement of processes and services to achieve ongoing customer satisfaction. It is therefore our policy to:

• Consistently provide quality services that conform to regulatory and customer requirements.

• Ensure that all personnel is competent and qualified for the tasks they perform and that all personnel familiarizes themselves with quality system documentation in order to implement the policies and procedures in their work.

• Professionally and effectively perform testing services to produce accurate and precise results.

• Consistently comply with ISO/IEC 17025:2017 Accredited to ensure quality testing services, and to continually improve the effectiveness of the Quality Management System.

• It is Cable Technology Laboratories' goal to encourage active participation of all employees in quality planning and continual improvement efforts to meet all quality, service, and cost objectives.

CTL's Customer Confidentiality Policy

Cable Technology Laboratories is committed to protecting the privacy of our customers by maintaining the confidentiality of customer records, transactions, and information in any medium (print, electronic, etc.).

Our Customer Confidentiality Policy is applicable to all employees here at Cable Technology Laboratories.

Our policy is interpreted to include, but is not restricted to the following:

• All customer information

• Databases and other files or materials consulted (i.e., Test Reports)

• Computer/Internet use

• Number and/or character of questions asked

• Customer visits to Cable Technology Laboratories

CTL's 40 Years

Milestones & Achievements

Participation in establishing the nature, and developing adequate testing approaches for water treeing in polymeric insulations

The invention of methodology to rehabilitate (rejuvenate) aged cables having XLPE or EPR insulation

Basic study of transient breakdown voltage in solid dielectric cables

Development of cross-linked polyethylene insulated cable for cryogenic operation

Establishing thermal overload characteristics of extruded dielectric cables

Development of a cable manufacturing process using dry-cured with internal pressurization

Aging study of distribution cables at ambient temperature with surges

Thermal issues and rating of separable insulated connectors

Development of criteria for VLF testing of extruded cables

Failure mechanism assessment of MV EPR cables

Development of methods to assess the condition of aged paper insulated cables both medium and high voltage (PILC, LPGF, MPGF, and HPGF, HPFF, and Self-Contained)

Numerous R&D projects resulting in the development of novel designs, manufacturing regimens, procedures, and test methods for cables and accessories:

- Heat-shrinkable accessories

- Cable moisture barriers

- Connectors for stranded conductors with impaired contact between strands (for instance, due to water blocking materials in interstices)

- The need for prompt testing of aged extruded cables after de-energizing due to the rapid regeneration of dielectric strength

Development and performance of customer-oriented test programs for supporting their quality assurance systems, including:

- Design, type, and qualification tests on all types of cables and accessories

- Acceptance, compliance, and claim testing

- Factory audits

- Witnessed manufacturing tests

- Failure analysis

- Comparative testing of alternative design and brand products

- Accelerated aging tests

Development of new test methods, procedures, and equipment for evaluation of the different types of cables and accessories:

- Torsion test for cables used in drip loops of wind turbine generators

- Evaluation of splice structure by measurement of contact resistance between individual strands and connector barrel

- Instrumental evaluation of soft spots in paper insulated cables

- Methods of finding and visualizing water trees in dark polymeric insulations

Evaluation of newly developed test methods and equipment:

- Very Low Frequency (VLF) method for diagnostic and maintenance testing of aged cable systems

- Several versions of partial discharge testing and monitoring systems

Line resonant test system (LIRA).

Failure analysis and research projects resulted in findings of significance to the industry:

- The need for additional steps in the pressurization schedule for high-pressure fluid-filled cables lacking oil

- The effect of intergranular corrosion cracking in flat strap neutrals of heavily loaded cables

- Overheating of accessory connectors in heavily loaded cable systems